Industrial Refrigeration

Proven performance, and fully customizable solutions

EVAPCO industrial refrigeration solutions have a proven record of performance for all types of applications in the industrial refrigeration industry. Extensive research and development, coupled with EVAPCO’s product application experience and state-of-the-art manufacturing capabilities, have made EVAPCO a leader in the supply of industrial refrigeration equipment.

From highly efficient evaporative condensers, to low refrigerant charge evaporators and the ready-to-go Evapcold all in one package, EVAPCO has a solution for any industrial refrigeration need. AHRI certified™ evaporators ensure guaranteed performance for any application.

CPA units, evaporators, and RVS pressure vessels can all be easily customized to suit any work environment. EVAPCO offers engineering expertise to design and build virtually any type of non-catalogued custom coil, special unit or package. We welcome the opportunity to meet you and discuss your custom application requirements.

- Unlike other adiabatic products currently on the market, the EVAPCO eco-Air Series units are 100% fully rated. Every eco-Air unit comes with EVAPCO’s exclusive 100% thermal performance guarantee

Unlike other dry products currently on the market, the EVAPCO eco-Air Series units are 100% fully rated. Every eco-Air unit comes with EVAPCO’s exclusive 100% thermal performance guarantee, ensuring

Unlike other dry products currently on the market, the EVAPCO eco-Air Series units are 100% fully rated. Every eco-Air unit comes with EVAPCO’s exclusive 100% thermal performance guarantee, ensuring

- Unlike other adiabatic products currently on the market, the EVAPCO eco-Air Series units are 100% fully rated. Every eco-Air unit comes with EVAPCO’s exclusive 100% thermal performance guarantee

Induced draft, counterflow condensers featuring the patented, high efficiency EVAPCO Ellipti-fin® Coil and EVAPCO’s ARID fin Pak® dry coil. The ultimate in wet/dry performance, every model has been engineered to provide a minimum 50% of the design heat of rejection (MBH) at 60F ambient dry bulb temperature or higher, based on a 96.3F (35.7C) condensing temperature.

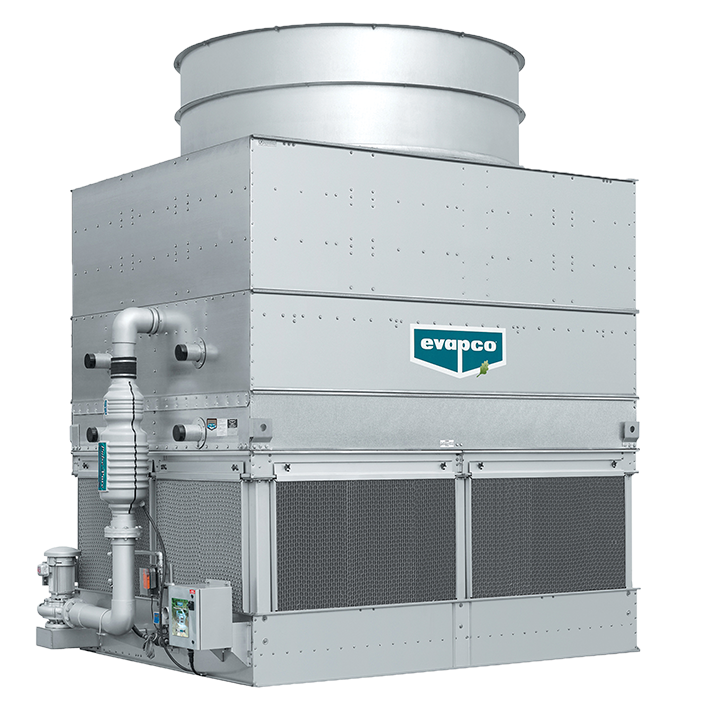

Induced draft counterflow condensers comprised of 181 models ranging in size from 50 to 3714 nominal tons (215 kW to 15,999 kW) designed especially for easy maintenance and long, trouble-free operation.

Low noise, low height, forced draft, centrifugal fan design evaporative condenser with a capacity range of 25 to 379 nominal tons (107 to 1633 kW).

Forced draft, axial fan models can reduce power requirements by up to 50% over centrifugal fan models of similar capacity. The PMC-E Condenser has more capacity than any other forced draft condenser on the market and provides more choices due to its greater number of plan areas.

Forced draft centrifugal fan condensers are very quiet and ideal for applications where noise is a concern.

The eco-PMC offers the same features and benefits of the PMC line of evaporative condensers but utilizes EVAPCO's patented ellipti-fin coil technology to offer water savings benefits through expanded dry operation.

- Induced draft counterflow evaporative condensers featuring signature AT features utilizes EVAPCO's patented ellipti-fin coil technology to offer water savings benefits through expanded dry operation. 122-3946 nominal tons